Solar energy has taken the world by storm for being one of the cheapest energy sources ever discovered. It has slowly become the hallmark of green energy by offering a clean, sustainable, and efficient method to produce electricity.

That’s why companies and households are installing solar panels to fulfill their electricity requirements and save money. The materials used to manufacture solar panels may differ based on their use and type. But the basic components which absorb sunlight and convert it into electricity remain almost the same.

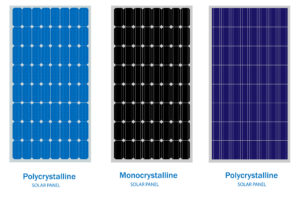

Most solar panels on the market are made of monocrystalline, polycrystalline, or amorphous silicon. Curious to know more about the materials? Continue reading to know more.

Contents

- 1 Key Takeaways

- 2 How Do Solar Panels Work?

- 3 What Materials Are Used For Making Solar Panels?

- 4 What Are The Components Used To Develop A Solar Panel?

- 5 Recent Advancements

- 6 Expert Insights From Our Solar Panel Installers About “What Are Solar Panels Made Of

- 7 Experience Solar Excellence with Us!

- 8 Wrap Up

Key Takeaways

- Solar panels are made up of photovoltaic cells, which can convert sunlight into electricity. These cells are typically made of materials like monocrystalline, polycrystalline, or amorphous silicon.

- Silicon is the most commonly used semiconductor material in solar panel manufacturing due to its affordability, efficiency, and durability. There are different types of silicon solar cells, including monocrystalline, polycrystalline, and amorphous silicon.

- Solar panels consist of various components, including glass casing sheets, metal frames, anti-reflective films, conductive strips, and plexiglass. Recent advancements in solar technology include solar roof tiles and glass solar panels, which offer new design options for solar energy generation.

How Do Solar Panels Work?

Solar panels consist of smaller units or components called photovoltaic cells (PV). There are also commonly known as solar PV, capable of converting sunlight into electricity. Many such photovoltaic cells are connected to form a solar panel.

These PV cells are placed between slices of semiconducting material, like silicon. The cells are supposed to create an electric field to work properly. As an electric field can only be produced when two opposite charges are separated, manufacturers mix other materials with this silicon.

It gives each layer of the panel a positive and negative charge, which helps create the electric field. Now, each layer consists of various electronic properties. So, when sunlight particles of protons fall on the panel, the electrons are knocked out of the atoms, generating electricity.

At first, solar panels produce a direct current (DC) of electricity, which is then moved to an inverter. It now gets converted into an alternating current, which can power up homes and electrical appliances.

Alternating current can also be passed on to the national grid for further use.

Will Solar Panels Work If It’s Cloudy Outside?

Yes, solar panels can work on cloudy days. These devices are capable of reacting to the visible light spectrum. So, if there’s enough sunlight outside to see, the solar panel can use it to start producing electricity.

Moreover, some solar panels are capable of producing electricity even in an overcast climate. But it won’t be as effective as it would have been on a sunny day. The stronger the sunlight, the better is the electricity production.

What Materials Are Used For Making Solar Panels?

Now that you’ve wrapped your head around the basics, let’s get back to what solar panels are made of. As discussed previously, the most important part of a solar panel is the semiconductor material used to absorb sunlight.

The amount of electricity generated by the cell compared to the amount of sunlight falling on it determines the efficiency of the cell. This will show how effective the panel is at converting solar energy to electrical energy.

Let’s learn about the types of semiconductor materials used to manufacture PV cells.

Silicon

Silicon is the most popular semiconductor material used for manufacturing solar panels. It is also a very common material used to develop semiconductors in computers.

This material has become widely popular because of its affordable cost, high efficiency, and longevity. Silicon solar cells are categorized into three types –

- Monocrystalline

- Polycrystalline

- Amorphous silicon

Monocrystalline Cells

These types of panels are developed from a large block of silicon and are made into a silicon wafer. The individual wafers are cut and can be fixed on top of one another on a solar panel. Due to such hard work, they’re a bit expensive but more efficient than amorphous or polycrystalline cells.

Polycrystalline Cells

These cells were launched in 1981. Their manufacturing process isn’t as complicated as monocrystalline cells. Polycrystalline solar cells are manufactured by melting several silicon crystals. Then, they are poured into square-shaped molds.

That’s why these are less expensive and offer decent efficiency.

Amorphous Silicon Cells

These are commonly used in thin-film solar panels and are non-crystalline. They are attached to surfaces such as metal, glass, or plastic. As a result, they are flexible and bendable, unlike a normal solar panel. However, the cells aren’t as efficient as polycrystalline and monocrystalline cells.

Perovskite Solar Cells

These are thin-film cells and have a crystal structure. They are developed using layers of material printed or coated on an underlying layer called a substrate. These cells are not very complicated to manufacture and are efficient like crystalline silicon.

Experts have stated that Perovskite cells improve efficiency and are better than any material ever used to manufacture solar panels. However, to be commercially popular, these cells must be durable and survive almost 20 years when placed outdoors.

That’s why scientists are working on it using modern yet low-cost manufacturing methods to enhance its longevity.

Organic PV Cells

Also known as OPV, the cells are made of carbon-rich organic compounds. These are unique materials and can be used to improve a specific function of the solar cell, such as transparency or bandgap.

Moreover, the material can be used against other supporting materials like flexible plastic, making it very convenient.

A lot of work still needs to be done on these materials, as they’re not very efficient like crystalline cells and have a shorter lifespan. However, they might be less expensive to manufacture and can be developed large-scale.

Just like the previous material, a lot of research is underway on this material. Its flexibility can prove to be useful and make it multi-purpose.

Multijunction Cells

The cells are made of multiple layers of semiconductor materials. Here, layers of different semiconductor materials are stacked together. As each layer comes with a different bandgap, a different portion of the solar spectrum is absorbed.

It allows the material to make better use of the sunlight than standard single-junction solar cells. Moreover, it can be highly efficient as the layer absorbs the sunlight beneath the first semiconductor of the panel.

However, these cells are expensive to manufacture, so they are only used for space exploration. Also, multijunction cells are able to combine with semiconductors from the 3rd and 5th columns of the periodic table to absorb more sunlight and generate electricity.

In those cases, they are called multijunction III-V cells. They are being used by the military for running their drones.

Concentration PV Cells

In these types of cells, a mirror lens is used as the material for focusing sunlight. Using the mirror, the sunlight is focused into a small area, and the light slowly becomes a lot more concentrated. So, the lens or mirrors make these cells extremely power efficient like other types of PV cells.

But in the long run, more costly manufacturing processes, materials, and the functionality to track sunlight will also be required for these cells. The quality of the lens also needs to be top-notch.

Therefore, even with excellent efficiency, their use and development will stay limited. Subsequently, more research is underway in this regard.

What Are The Components Used To Develop A Solar Panel?

Apart from solar cells, there are other components that come together to make up a solar panel. In this section, we’ll have a look at them.

Solar Cells

As you probably know by now, these are the most important component of any solar panel responsible for converting sunlight into electricity. They are installed in a matrix structure between the glass panels. When these cells interact with the glass wafer sheet, an electric charge is developed, which eventually leads to electricity generation.

Glass Casing Sheet

They are included for protecting the solar cells from within and are usually 6-7 millimeters thick. It also allows the cells to be in position.

Metal Frame

This is usually made of aluminum and is used for protecting the panel from harsh weather conditions and damage. That’s why they need to be extremely sturdy, as they also play a vital role in the installation and mounting of the panel properly.

Anti-Reflective Film

This film is added on top of each solar cell to increase and maintain its efficiency. The layer prevents sunlight from being reflected away and steers them towards the silicon for better absorption. Solar panel manufacturers often use titanium oxide or silicon nitride for developing this film.

Conductive Strips

All solar panels include conductive metal strips that are responsible for receiving and transporting the current generated by the electrons in the silicon material. A particular solar cell looks like a triangle or a square and is combined with other cells using these conductive strips.

This combination allows the cells to transport all the electrical energy to a location. The electricity can be sent to an AC/DC converter or a battery. Bus wires which connect the solar cells in parallel allow easy movement of the electric currents.

Plexiglass

This is a very important component used in solar panels to allow almost 90% of the sunlight falling on the surface to reach the cells. It is highly durable and can be conveniently cut and shaped as per requirements.

At the front of each solar panel, there is a glass casing added to protect the silicon material. Beneath this glass surface, there is another glass casing added to provide insulation. Moreover, there’s a back sheet, which reduces humidity inside the panel and heat loss.

The insulation layer is essential to the panel because there may be a decrease in efficiency with the rise of temperature. As a result, the final electrical output of the solar panel will be low. Both front and back glass sheets help in retaining heat and balancing the distribution.

Recent Advancements

Solar panels have come a long way in terms of their design and functionalities. Nowadays, solar roof tiles are gaining popularity due to their compact design and efficiency. They look like standard roof tiles and can also be installed like them.

So, you can pack in multiple solar roof tiles together to generate more electricity.

Glass solar panels are also making the rounds in the industry. These modern solar modules won’t require opaque backing components and can use the clear glass surface to generate electricity.

With these systems, your windows and skylights can easily absorb sunlight and produce electricity.

Expert Insights From Our Solar Panel Installers About “What Are Solar Panels Made Of

Understanding the materials used in solar panels is crucial for optimizing their efficiency. Silicon, especially monocrystalline, offers high efficiency and durability, making it a popular choice for both residential and commercial installations.

Senior Solar Technician

Advancements in solar technology have led to innovative materials like perovskite and organic PV cells. These materials hold great promise for future solar panel designs, potentially offering higher efficiency and flexibility at lower costs.

Lead Solar Engineer

Each type of silicon cell—monocrystalline, polycrystalline, and amorphous—has its own set of benefits. Monocrystalline cells, for example, provide the highest efficiency, while polycrystalline cells offer a more cost-effective solution without significantly compromising performance.

Solar Installation Specialist

Experience Solar Excellence with Us!

Trust in Solar Panels Network USA, where our seasoned experts deliver top-quality solar solutions for homes and businesses nationwide. With a legacy of countless successful installations and a commitment to sustainable energy, we’re your reliable partner in the solar journey. Ready for a brighter, eco-friendly future? Call us now at (855) 427-0058 and harness the power of the sun!

Wrap Up

Solar panels are one of the most groundbreaking inventions of the era, thanks to the materials that are used to develop them. Silicon still remains the best material in terms of efficiency and manufacturing convenience.

However, extensive research is constantly going on to uncover better techniques to reduce costs and enhance the efficiency of these panels. As the solar panel industry is becoming extremely competitive, it might take over traditional energy sources.

About the Author

Solar Panels Network USA stands at the forefront of solar energy solutions, driven by a team of seasoned solar engineers and energy consultants. With over decades of experience in delivering high-quality solar installations and maintenance, we are committed to promoting sustainable energy through customer-centric, tailored solutions. Our articles reflect this commitment, crafted collaboratively by experts to provide accurate, up-to-date insights into solar technology, ensuring our readers are well-informed and empowered in their solar energy decisions.